I was lucky enough to attend a talk recently by Neil Collison, of Knitting Machine Repairs, at the Long Buckby machine knitting club, and took these notes. Hopefully they will help others who for reasons of geography cannot use Neil's excellent services. I left my faulty garter carriage with him - it would sit on the bed and make all the right noises, but only knit a few stitches and then sit there chugging away and not moving. He returned it very quickly and replaced a circuit board. The only hitch in the whole transaction was that my email provider refused to accept his, so invoicing ended up being done via Whatsapp!

Brother sinker plate

Remove yarn from around brushes

Brush wheels can be replaced with rubber ones

Lubricants

Gun oil (not bore oil)

Sewing machine oil

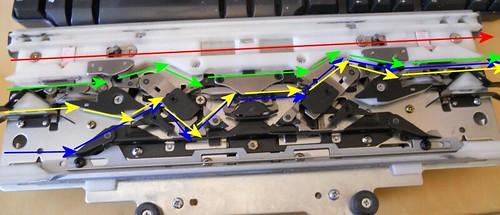

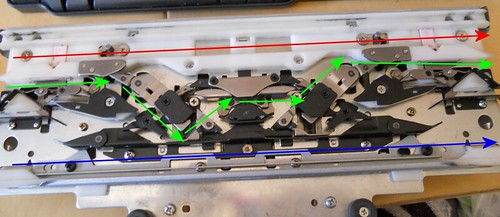

Retainer bars

Spartan or Andeeknits in the UK, they are ordered in bulk from Germany

Maintenance steps

Push needles to UWP, use clean paintbrush to brush out the needle strip area and the back rail area

Run a finger along the needles, the latches that don't drop back are bent

Open all latches, push down quite hard. Use a piece of paper to flick the latches shut.

Return the needles to A position. Stroke along whilst pushing forward, this checks the needles for straightness

If any needles get jammed low in their channel, you may need to release the patterning belt to free them.

Cleaning

Neil uses a solution of 2 parts iso propyl alcohol to 1 part surgical spirits. This is used to soak stuck components eg stuck buttons (requires some carriage disassembly). Items should be soaked for a few seconds and then wiped off. You can also use the paintbrush to get the solution into difficult areas. Disassembly of the plastic lid from the carriage is done by loosening the brass coloured screws.

For needles, use surgical spirits with a few drops of oil in a jar. Soak needles for an hour. You can clean needles in situ - when the retainer bar removed, wipe in HOLD with the cleaning fluid, push them down and put them back into position and clean off.

Use a clean paintbrush dipped in the oil/spirit solution to clean the front rail. You can also use cotton buds dipped in the solution to clean small, tight areas eg rails, slots on the underside of the carriage.

If you are doing a full clean, use a cat tail brush to clean out the retainer bar slot. If you put a small 90 degree bend in the handle end of the brush, you can use it to retract the brush easily by winding it back out.

Knitmaster drums: use WD40 to loosen seized drums (this was the only time he would use WD40).

Plastic parts: Flash all purpose cleaner is fine for plastic parts

The carriage underside: apply the gun oil to the two large cams. Rub it into the grooves using your fingers. Oil the front and rear rails.

Passap jaws: apply surgical spirit with the jaws open. Passaps take 6 to 8 hours to service. Brush out the needle slots with surgical spirit only and a toothbrush. When all has been cleaned, replace the middle 40 needles on both beds, set to N/N and “air knit” for a bit to bed in the needles. Add 10 needles each side on both beds, repeat until all needles are back in place. Repeat this with the pushers. Set front and back beds to alternate the pushers every row.

exhausted

exhausted

exhausted

exhausted