Well, it's been an interesting few weeks, none of which had to do with my creative side - it does stop my creative side from happening though. And no, Anonymous (previous post), I didn't invent the Ravellenic games just for fun. Someone at Ravelry came up with it quite a while ago. It was originally called the Ravelympics until a ceast and desist from the IOC meant a name change (though they did later apologise, you don't want to mess with outraged crafters!). For my part I'm sure the Greeks would be on our side, Mount Olympus being a place, but rules is rules, and Ravellenic was voted the most popular alternative title. It's now all rather ironic seeing as Tom Daley shared a post of another lovely sweater he made during the games, though I do think he needs to learn the difference between intarsia and fairisle. The floats he gave himself around the lower edge of that sweater for the various flags are just begging to get snagged on fingers and pulled out of shape! So anyway, the Ravellenic games run alongside the Olympics; the idea is that one casts on during the opening ceremony, should it concur with your time zone, and to challenge oneself to complete at least one project before the closing ceremony. No monetary prizes are awarded, it's all just a bit of fun, and the "medals" for tagged events (eg sock heptathlon, sweater long jump) and "laurels" (for specific techniques eg beading, cables) are just fun pictures to save, download and share. The machine knitting team named itself Team Rise of The Machines after the Terminator movie of the same name and it stuck... and I usually design the team logo just because of my background in graphics.

Incidentally, the title is a sideways tribute to one of my favourite songs, by one of my favourite bands. I was sorry to learn that Aerosmith is no longer touring due to ongoing problems with Steven Tyler's voice. There's a price to pay for being the Demon of Screamin', alas.

Anyroad, thanks to the mental funk, I've just not felt up to doing much - couple that with a 10 day heatwave, and manhandling yarn in an upstairs room that feels like it's doubling as a pizza oven just isn't my preferred way of spending time.

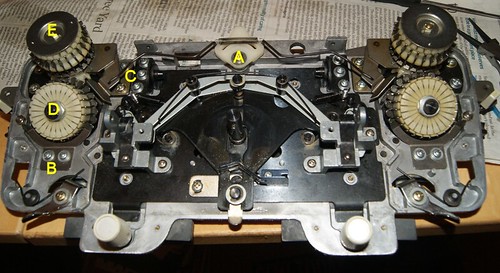

My good friend C recently gifted me with one of her Ebay purchases - a Knitmaster 260k machine. It was naked of everything except its empty accessories box, so I'm gradually putting it all back together so it can become a second workshop machine. I discovered to my chagrin last week that Brother and Knitmaster C clamps are NOT interchangeable - the latter are thinner, so the Brother ones literally won't slide into the slots. I scrambled, as my monthly club meeting was about to start, and used the ribber clamps from my SRP60N in the end, mostly because accessing the ribber box was quicker than trying to dig out the SK840 itself (and one of those clamps keeps falling off anyway, I think the thread is worn beyond repair). So after last week's disastrous attempt to demonstrate machine lace (the lace carriage drums were seized, all good again thanks to one of Ask Jack's great videos!), I thought it was time to put the machine through its paces. Alongside all that, I rediscovered a box of punchcards acquired from an estate sale. They're in one of those old vinyl boxes, very similar to the much beloved cases of my late father and his audio cassette collection. Reading the manuals (something I fail to do as often as I should), certain devices call for the ribber clamps anyway - my YC6 seems to have a single ribber clamp in the box, no idea where the other one is!

Anyway, the first card up was a hand-punched card that just said chunky slip 901. It was mostly holes but with some unpunched alternating strips. It knits a very striking slip stitch fabric, somewhat akin to holding position in random places (but holding creates tucks, slip just means the stitches stay hanging on the machine whilst knitting happens around them). I think there's a version of this called "tea cosy stitch", which was how those old traditional striped tea cosies were knitted. It works well as long as you never have end needles slipping, because things hanging up on ends is a bit of an issue for weighting reasons.

Second up was a mystery card - it said two colour single bed slip, but other than trying to read the pattern or enter it into DAK, the quickest way to read it is to knit it. After about 20 rows being one row out, I discovered someone had attempted to replicate a fairly standard dogtooth check pattern - alas the pattern had errors, so went into the bin. Single bed slip like this is a not-often used technique, only Passaps have to do fairisle like this because they've only the one yarn feeder in use at a time.

The third card was a bit of fun - I've two very long cards punched with dragons and yin-yang symbols. I'd like to transfer this into DAK and do some float control. Or this could be a great technique for ladder back DBJ - something I need to explore more! This would make an amazing sweater, I do wish I had some provable Welsh or Japanese ancestry!

Pulling the leading end needle out forces the second yarn to knit to the edges and eliminates tangles and other problems.

The final card was a bit of a punt. The machine in question came with no punch cards, and although I've got a set which will work with the main bed, the lace cards I thought I'd found for it turn out to be for a two carriage lace system, and I couldn't find any Knitmaster lace cards to try. I eventually found a card someone had punched which at least proved that the lace carriage is now working. I've a dodgy needle to remove, and all of the needles need removing and soaking, but it was, all in all, just what the doctor ordered in that it got my crafting mojo back a bit, even as far as filing some of my new samples into my lever arch collection! :) Next task, asides from the needle cleaning, is to test the machine with the ribber!

So, if you're in a crafting funk - just push play. The clouds may lift sooner than you think!

Current mood:  okay

okay