Life is continuing to be busy here, so I'm not getting on-line much. I've taken up Nordic Walking which is really fun in an effort to sort out my back/knee issues. When I've come back from a session I'm good for nothing except tea and slobbing in front of the sofa, a bath, and bed. There has been some machine knitting - notably, a one day's workshop with

Manor House last week on how to produce hairpin lace style strips on a knitting machine - but I've nothing finished to show yet. Almost, but not quite. I'm part way through sewing up another charity sweater, and discovered last night that the second cone of brown acrylic wasn't at all the same colour. Drat. I've finished hand knitting all the parts for the bamboozle cardigan, so need to join the shoulders before I can continue adding the bands. I'm on the last front of the Blusa Queen, but it's slow going as I've got to figure out neck decreases (in lacy crochet). All of this takes time, patience, good light, good sleep, none of which I have in abundance at the moment. The sore knee in particular is disrupting my sleep, because the only position I can sleep on is on my back, and I prefer the foetal position. So I keep turning over and waking myself up in pain :(

Anyway, I made a very simple shawl ages ago, and have been trying to get a decent photo of it ever since:

It's some sort of very fine silky acrylic, and I made it by casting on 3 sts and increasing every other row. Because I had planned to make this with a lace pattern, and because the yarn is pretty much too fine for the lace carriage to handle, I resorted to hand transferring every other needle every 20 rows. It's lovely, light and drapey, and the photo really does not do it justice.

This was inspired by Tony Bennett's introductory talk at Dream Week - wire knitting with beads!

Again, not a great picture - the perils of indoor photography in autumn - it's a fine strand of wire knitted over 4 needles EON and there's a seed bead in every gap, every other row. This is all hand-manipulated on the machine, as the beads were pre-threaded and I couldn't figure out how to handle that plus the carriage - and it's hardly worth threading the carriage for only one pass out of two anyway. The KH950i is one of my favourite machines and not one I want to sacrifice to el cheapo broken glass beads that came free with a magazine. It went surprisingly fast once I removed a very curious cat (who just ADORED the wire) from the equation. It's long enough to make a choker or something and can be moulded a little to suit the wearer. I need to have a dig about and see if I can find some findings to finish it off.

And news just in, the venerable

Texere Yarns has gone into liquidation. I'm gutted - I had my eye on some of their Good Fortune cotton but was waiting 'til next month when I'm more solvent. I wasn't one of their biggest customers, by any means - I've only ordered a few cones of Jura (which was lovely!) - but the service was prompt and efficient and they had just about every kind of yarn you could think of on their website. My condolences to the team - not the best time of year to be made redundant :(

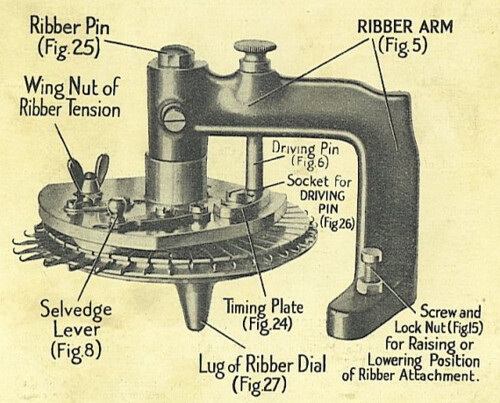

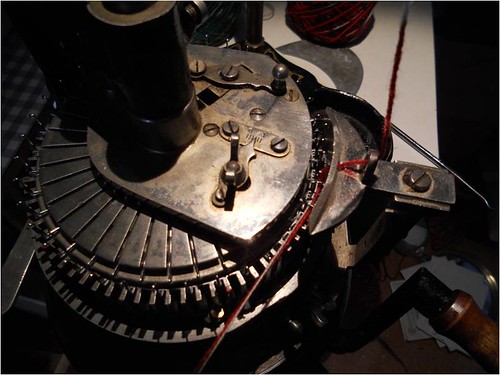

I acquired a vintage 1950s Record knitting machine on Ebay some time ago - it's a very basic machine, the best description of it is a mechanised peg knitting loom - so no overhead mast and no needles. It can produce stocking stitch and garter stitch, and it was the latter I bought it for. Ironically, a few weeks later a local lady gave me two knitting machines to be donated to charity, and - yes, you've guessed it - one of the machines was another Record. The other was a Brother KH710 which needs a really good clean up and a new bar, but appears to be complete - if anyone's interested please email me! I've emailed TWAM about it and had absolutely no response so I'm rather annoyed about that.

Anyway, we've been having a serious sort out of the garage - himself is planning a man cave / gym / guitar studio - and he really wants the knitting machines out of his space (we shall see! some of them I'm keeping!). But I thought I'd get the Record out and have a play. The instructions are very sketchy - luckily for me, a fellow Raveller has made an excellent video of how to knit on a Meda, which is a mini version of the Record.

Thanks Pirvonen!

Basically, you do an ewrap cast on onto a comb with pins, and mount it in front of the machine. You slide the first knob to one side, which makes yarn sinkers pop out between the pins. You lay yarn in the channel this creates, and then slide the second knob to close the sinkers again. Then you pull the knitting upwards and make the stitch (on the first row you have to do this with a small hook, I used a DPN). Then you pick up the comb (knitting attached, hopefully - pull it down!) - and turn it 180 degrees for the next pass. Simple.

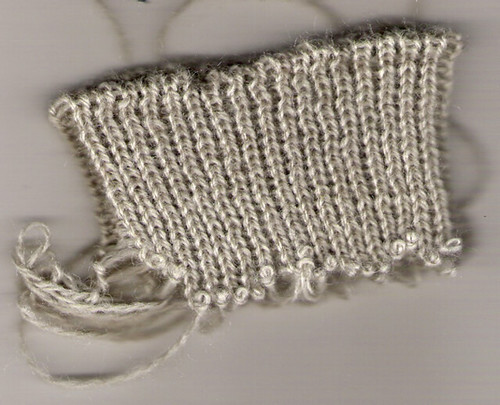

I got quite a nice piece of garter stitch knitted - ignore the great big loop on the first row, the instructions said something about making sure you went a few pins past the first pin, but it looks like it wasn't necessary.

I'm not sure I'm going to keep the machine - it'd be great for someone who needs a LOT of 4ply garter stitch. The donated one is so gunked up it's only destination will be the tip, unless someone wants it for parts. But the other one is in excellent working order - although, I didn't try the stocking stitch comb - why would I, when I've a stable of more modern machines upstairs?! :)

Last night I foolishly cast on some more fairisle socks to be finished on the CSM. These are white with a red heart motif. I went for my first proper nordic walk last night and was so tired I didn't get started on the machine knitting until gone 9pm (which included designing the pattern on the PPD), so it's a moot point as to whether I'll have the socks finished for Thursday night. Yeah, I know, forgot there was an annual competition! On the positive side I've finally figured how to get switch 5 (reflection) to create upside down patterns - the KH950i has to be in 990 mode not 999 mode. Yes, it IS in the manual. But who reads those?! :)

Current mood:

exhausted

frustrated

frustrated

exhausted

exhausted